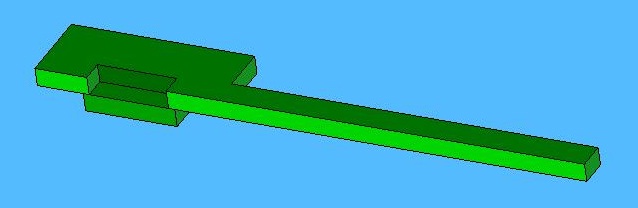

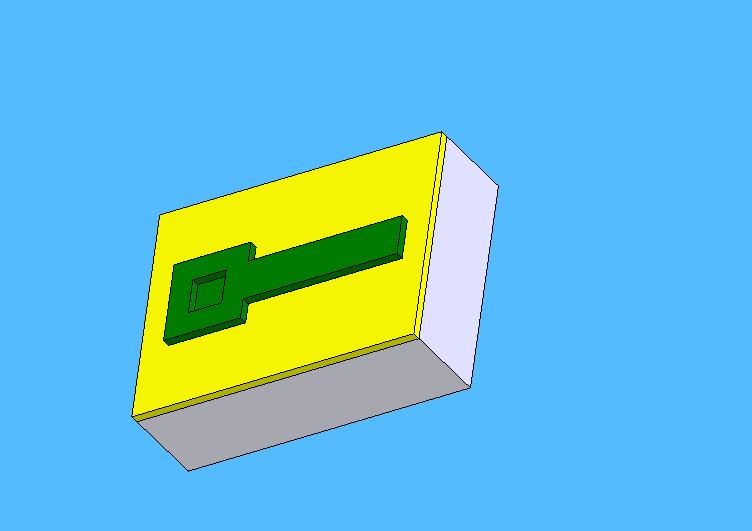

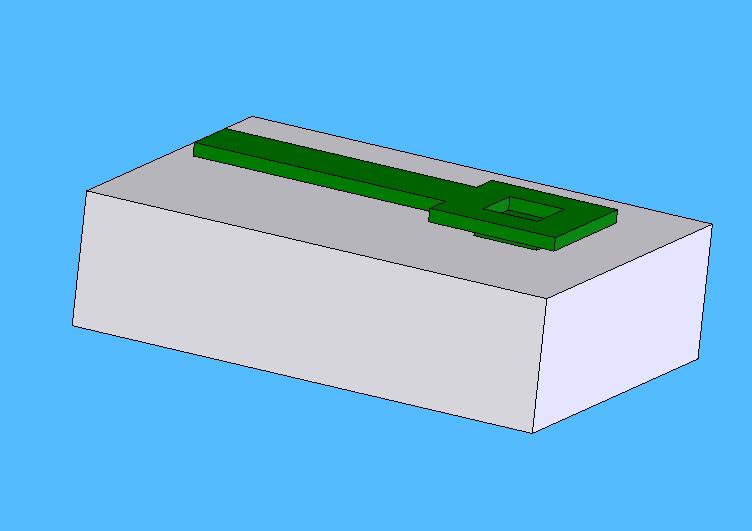

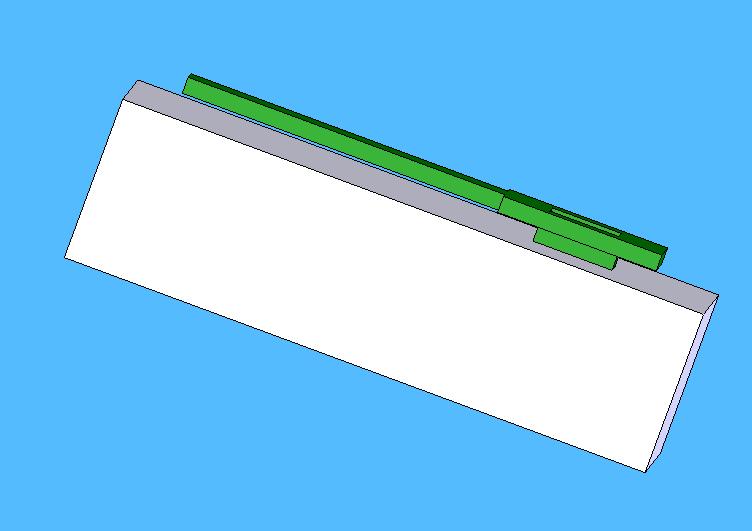

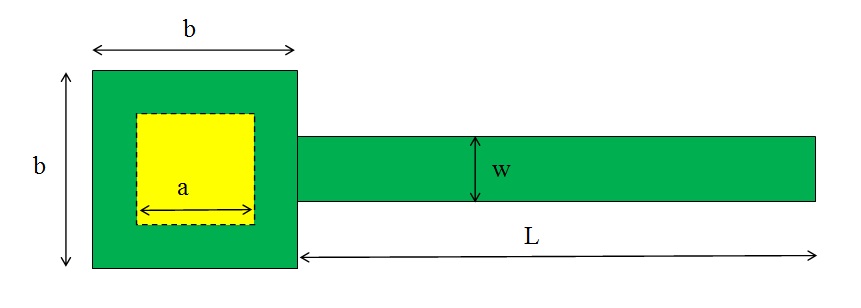

Consider the geometry of the surface micromachined cantilever beam whose section-view is shown in the figure below. The figure is NOT TO SCALE. Also shown below is the model of the structure before the (yellow) sacrificial layer is dissolved and two views of the released beam. Or, download the pdf file that has a solid model of the released beam that can be rotated and seen from all directions. And this pdf file contains the rotatable section-view of the beam. These pdf files run Acrobat Reader 8 and later versions.

It is made as follows: On a (100) silicon wafer, 1 um thick oxide layer is grown and patterned to leave to square hole of 50 um side. A polysilicon layer of 2 um is deposited on top of that and this layer is patterned to leave a T-shaped island. The oxide layer is sacrificed in the end. See masks in the figure below for clarity about the dimensions.

a = 50 um, b = 90 um, w = 30 um, and L = 300 um.

Assume that there is a load at the free tip of the released cantilever beam. Let the force be F = 0.1 uN. Analyze this beam by making the following modelling assumptions and compare them with respect to the deflection of the point where the force is applied. Young's modulus of silicon may be taken to be 169 GPa.

- Consider the entire beam and assume that it is fixed at the portion where it is in contact with the substrate.

- Consider only the horizontal portion of the beam (i.e., the overhanging T-portion)

- Conisder only the narrow-beam part of the overhanging T-portion.

- Use cases 2 and 3 with a torsion spring with a hinge joint instead of built-in support at the left end. What torsion spring constant gives you an answer that agrees with that in case 1?

Extra credit of 30 points for arriving at an expression for torsional spring constant of case 4 in terms of the anchor size (i.e., the square hole size in the oxide layer and the wide part of the T-shaped island of the polysilicon layer) and the thickness of the oxide layer.